What goes into making an LED Strobe Light for Emergency Vehicles

Posted by Extreme Tactical Dynamics on Oct 12th 2020

One of the most interesting things about LED lights is that even today, the range of types and varieties available is still increasing all the time. They have so many uses and there’s an interesting timeline to explore in terms of their development and usage. And that’s exactly what we’re going to delve into today.

We’re going to find out how LED lights are made, as well as focusing on emergency vehicle lights and how their usage came to be. There’s a lot to talk about and a lot to explore, but if you’re interested to learn more about this topic and everything there is to know about the background of LED lights for emergency vehicles, you’re in the right place. We’ll begin with an introduction to LED lights and explore the topic from there, so start reading now.

LED Lights: An Introduction

It’s time to consider what LED lights actually are, why they’re used and what kind of science is behind them. These are all important questions when it comes to understanding LED lights, as well as the kind of LED lights an emergency vehicle would use. Find out more below.

What Makes LED Lights Different?

The first thing to know about why LED lights are appealing and why they’re increasingly used as alternatives to standard light bulbs is the fact they’re highly energy efficient. Incandescent bulbs are less efficient because a lot of energy is used on passing an electric current through a filament, producing heat. This means energy is being used before any light is even produced.

That’s where incandescent bulbs are different from LED bulbs. LED bulbs are far more efficient and they actually use 90% less energy than incandescent options. There’s no energy wasted in the process and the energy that’s used goes straight to producing light, making them a better lighting option.

Many places, including the EU, are now actively banning incandescent light bulbs. And this is all because of how inefficient they are. It has become clear that LED lights are simply much more efficient, making them greener and more cost effective. The widespread uptake of LED bulbs, especially when used in police lights, should come as no surprise and the trend is only set to carry on increasing in the months and years ahead.

The Science Behind Them

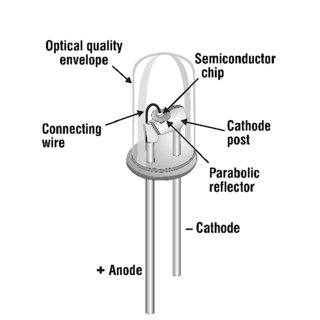

Now it’s time to really delve into the science behind LED bulbs. Each one consists of multiple light emitting diodes, which is where their name comes from, and together they create light once an electrical current passes through them. This process produces photons, which is what results in the creation of light.

They are regarded as solid-state lighting and this is because light is emitted from a solid semiconductor and there’s no glowing filament involved in the process as there is with incandescent bulbs. This process is what makes them efficient and results in 40,000 hours of life. That difference is enormous and makes replacements far less frequent.

When you compare that to the 1000 lifespan of an incandescent bulb, it’s clear that there’s no competition in terms of which of these options is more efficient than the other. An LED light requires just 10% of the electricity used by an incandescent bulb and they produce the same amount of light, so there’s no drawback to making the switch to LEDs.

Are There Any Safety Issues?

There aren’t any safety issues known regarding the use of LED lights, and that’s something that also makes them more appealing than many of the alternatives out there. When you’re looking to light a home or a commercial space, one of the key things that has to be taken into account is of course safety and it’s something that can’t be overlooked these days.

One of the most significant factors in the safety of lighting is the DC voltage, which is 12 V for LED lights. That’s the level at which they operate and it’s considered very low, which is what you want from a safety point of view. This combined with other factors make LED lights a lot safer than other lighting options out there.

Even when compared to other energy efficient lighting sources, LEDs can be considered safer. For example, LED bulbs don't emit any polluting radiation which is important because that can be hugely hazardous and it’s a problem that some other light sources do face. Generally speaking, there are no safety concerns surrounding LEDs.

The Benefits of LEDs

Aside from the safety of LEDs, what else makes them appealing and beneficial? Well, it’s clear that people using LEDs over traditional incandescent light bulbs will save themselves lots of money on bulbs over the years. 40,000 hours of usage is a huge amount and it means that 1 LED source can last 40 times longer than an incandescent bulb.

Those are big savings, but when it comes to wider discussions about efficiency, it’s less about saving money and more about saving the environment. LEDs are the most efficient form of safe and reliable lighting that’s available today and that’s why so many homes and businesses around the world are starting to use them, and the environmental benefits are huge.

In terms of their performance, they start working right away and don’t take time to warm up in the way that incandescent bulbs do. So with better levels of performance and the potential to last for anywhere between 25 and 40 years of usafe, it’s no surprise that they’re being used more than ever before.

The Drawbacks

Now that we’ve talked about the benefits of using LED lights, it would only be far to also talk about some of the perceived drawbacks as well. In truth, there aren’t many of them. The acceptance of LEDs as the best lighting option in many circumstances is pretty unanimous; there aren’t many dissenting voices arguing against it at all.

The only thing worth mentioning is the upfront cost of LED bulbs compared to other kinds of lighting sources. You do have to pay more when you buy each new bulb or light, but those upfront costs are balanced out by the fact that they last so much longer, meaning you save money in the long-term even if you have to pay more now.

All in all, the case for LEDs has been proven and they’ll soon be ubiquitous around the world. Until there’s a new lighting solution that offers all of the same cost, efficiency and environmental benefits as LEDs, there’s going to be no better option than LEDs themselves, and next we’ll learn about how they’re made.

How Are LEDs Manufactured?

Now it’s time to find out how LED lights are manufactured and what the most important parts of the process are. It’s an interesting process and there’s more that has to go into than you might imagine, especially because of the delicate nature of LED lights. Here’s what you need to know.

Materials Used in Manufacturing LEDs

As we’ve already explained, LEDs are made from a series of small diodes and each one of these is made from a semiconductor material. Light is created via electronic excitation as the electrons move from between the layers of material. The semiconductor material that’s used to make the diodes comes from crystalline and impurities are added during the manufacturing process, which allows them to conduct electricity.

It might sound strange that impurities need to be added to the materials to make them function, but this is just a part of the process. It has to be done in order to make the diodes operate as they need to, and it should be seen as a process of enhancement, so don’t let the word ‘impurities’ mislead you. These impurities come in the form of nitrogen and zinc in most cases

Aside from the diodes, there obviously need to be wires in place as well. These are often made using silver and gold compounds and this makes the process of soldering them and putting them in place much easier. The diodes themselves have to also be encased in plastic that’s transparent, as I’m sure you’ve seen before.

The Design Process

There is a lot more scope for design flare and variation than many people realise when it comes to designing and creating LED lights. Many people assume that they’re all pretty much the same, but there’s a lot that can be done to affect the composition of an LED and therefore the final output is produced. And this is all part of the design process.

Things such as the colour temperature, brightness and things like that can all be changed during manufacturing once design decisions have been made. Changes to the sizeof the diodes, the materials used in production and the various types of impurities all have an impact on the finished product.

Another thing that can be changed according to the design needs and the desired light output is the thickness of the diode layers that are used. Different thicknesses of the various layers will change how the light is emitted when the final LED light product has been created.

The Careful and Delicate Process of Making LED Lights

You might not realise it, but the process of actually manufacturing LED lights is one that’s very delicate and has to be done very carefully indeed. It’s very complex, and it starts with the creation of the semiconductor wafer, which is created using very high temperatures and a pressure chamber. The various elements are purified and mixed together in the chamber and these include gallium, arsenic and phosphorus.

When that process is complete, the solution will have crystallised and results in a cylindrical crystal ingot. It can then be sliced into small semiconductor wafers and the surface is made smooth through a sanding process. Any dirt and debris is removed by cleaning it in a solution of solvents. Additional layers that can then be added, including adding impurities.

Metal contacts then have to be added to the semiconductor material, and it will differ depending on the design. It will also depend on whether this is a light that is going to be used singularly or in combination with other LED lights.

Mounting and Packaging

Next is the process of mounting the LEDs. They have to be mounted so that they can be used because in their pre-mounted state, they can function but they can’t be practically used. During this process, the right wiring has to be attached as well to make them fully functional as electrical lights, which is of course vital.

The mounting process is about putting them in the relevant surroundings depending on how they’re going to be used. The size and scale of the mount will depend on the LED light and what it’s going to be used for. It will usually have to be thought out in the design process. Once the mounting process is complete, they’ll be ready to encase.

The encasing stage is about covering the lights with a plastic case the same way a regular light bulb is encased. When they’ve been fully encased, mounted and had the right wires attached, they’ll be ready to go and should be fit for purpose, whatever the particular purpose and function of the LED light may be.

Distribution

When they’ve been put together and all of the things discussed above have been completed, they can be distributed to wherever they need to go next. In some cases, this will be directly to the user or the retailer who then sells the LED light products on to the end user.

It might also be the case that the lights will go to another stage of the manufacturing process. For example, when it comes to LED strobe lights for emergency vehicles, the lights will need to be taken to the place where the vehicles are being manufactured. They will then be attached in the relevant places where they can be used by the vehicle going forward.

The distribution process is something that’s pretty variable but there’s always a pre-defined plan for where and how the lights will be sent out to, and it all depends on the particular situation and the arrangements that the manufacturer has in place with other manufacturers, retailers or clients.

The History of the Usage of LED Lights

There’s a long and interesting history behind the usage of LED lights and we’re going to assess how that history unfolded. Perhaps most interestingly of all, our understanding of LED lights and what they’re capable of doing in terms of usability is something that we’re still learning about and uncovering.

The First Practical Usage of LED Lights

The first time an LED could produce a visible red light was in 1962 when Nick Holonyak Jr made this breakthrough. Before that, experiments into lights and gallium arsenide semiconductors had been ongoing since the 1950s. Holonyak Jr, who was working for General Electric at the time, is still regarded as the father of the light emitting diode.

It was in 1972 that M. George Craford at the Monsanto Company made the first LEDs that were capable of emitting a pale yellow light, and the company would later go on to make the first LED lights intended for mass market consumption. The lights created by Craford were capable of emitting a light that was around ten times brighter than the lights that Holonyak Jr developed a decade earlier. A few years later, LEDs capable of emitting pure green light were developed too.

Around this time, LEDs started to be used in relatively low cost and basic devices. They didn’t have a widespread or significant usage at this point and that’s something that wouldn’t come about until a little later.

Super-Bright Red, Yellow and Green LEDs

In the early 1980s, the first generation of super-bright LEDs was developed. This was a big breakthrough in LED technology and led to not only improved levels of performance in LED light technology but also the development of new colour outputs and even greater levels of efficiency from LED lights. It was a big deal at the time and provided the foundations for LED technology as we know it today.

In the beginning of the next decade, new developments in colour production were made. This is when ultra-bright orange-red, orange, green, and yellow LEDs were first created. It was a big step in the right direction and pushed forward the development of LEDs as we know them today.

The next breakthrough was in ultra-bright LEDs. The person responsible for the creation of ultra-bright red, yellow and green LEDs was Shuji Nakamura in 1994. It was an important breakthrough and it preceded the development of an even bigger breakthrough LED product, the white LED light, we’ll talk more about that later in the next section.

White LED Technology

Another important breakthrough in the development of LED lights that’s worth mentioning is the creation of white LEDs. This is something that also led to new options and new possibilities for LED lights and it came off the back of work and research done in the mid-1990s. The breakthrough was made using indium gallium nitride.

The discovery of white LED lights was made when scientists tried coating blue LED chips with fluorescent phosphors. The result was an LED that was able to emit bright white light and thereafter, white LEDs were able to be produced and manufactured on a large scale for a wide variety of purposes and functions.

This is when it became a priority for government departments including the U.S. Department of Energy to start encouraging businesses to use LEDs. With the introduction of white LEDs, it became possible for all kinds of businesses to start lighting their work areas with LEDs that did the same job as incandescent bulbs but better and more efficiently.

The Popularity of LED Lights Today

The popularity of LED lights today is beyond question. It’s very clear that LEDs are moving ahead of all other types of lighting and that’s not something that’s likely to change anytime soon. Although upfront costs remain higher, their longevity and energy efficiency make them more appealing to households, businesses and government institutions the world over.

Today, there’s a wide range of colours and types to choose from when it comes to LED lights. This variety is another part of what makes them so appealing to so many people. They can be used in many ways; they cover everything from fairy lights to regular bulbs to spotlights and strip lighting. Just about every type of lighting can be provided by LEDs.

The uses of LED lights are practical and decorative and prove to be great investments. When making the switch to LEDs, businesses in particular can save a lot of money and energy over the long-term, especially if their lighting needs are relatively high compared to homes.

The Future of LED Usage

It’s very interesting to think about the future of LED lights and how they might be used going forward. LED lighting is already being experimented with in conjunction with other technologies. For example, they can be used with wifi and might be able to steam information and potentially give details on how many hours of life they have left.

There have also been experiments into using LED streetlights that flash when there has been an emergency call made in the area. It would help emergency vehicles to get to the scene of an incident and know where it is sooner, meaning less time is wasted. That’s obviously something that’s very important when it comes to people requiring quick medical attention and other such situations.

It’s clear that the use of data will become a part of how LED lights function going forward. It’s hard to predict with absolute certainty how LED lights will be used in the years and decades ahead of us. But one thing that is certain is that the development of LED lights and their usage has not yet reached its climax. There’s more still to come.

LEDs and Emergency Vehicles

LEDs have been used in the manufacturing of emergency vehicles for a long time now. But why are LEDs seen as preferable to other light options when it comes to the vital flashing lights we associate with ambulances and other emergency vehicles? We’ll answer that and more below.

Rotating Lights and Strobe Lights

The first kind of lights used by emergency vehicles were steady burning lamp lights. They are still used in combination with other kinds of lights. Other kinds of lights that were used and still are in some circumstances are rotating lights. These use one bulb that stays still while a mirror spins creating a rotating beam of light that appears to flash when you see it. These originally used incandescent bulbs but now use LEDs instead.

Rotating lights can be used on their own in a single beacon formation or as part of a bigger light bar. Emergency lighting is often based on a strobe lighting effect. This employs a method of using short flashes of light that repeat over and over. Those short flashes have now been replicated using LED lights, where they were previously a necessity because of the use of xenon flash lamps.

As LED technology developed and became more advanced, the old forms of strobe lights were swapped out with efficient LEDs, but in essence, they perform in the same way and produce very similar light effects. One difference is that there’s now more precision and control over the light output thanks to the use of LEDs.

The Introduction of LED Lights

LED lights marked a big transition for how emergency vehicle lighting, such as those found in firefighter lights, was used and employed. There are many reasons why they grew in popularity and began to change the way in which we think of emergency vehicle lights. First of all, they’re very small and this means they can be used in a variety of ways and are much more versatile and flexible in terms of their usage.

When it comes to the use of LED lights on emergency vehicles, it’s all about control. What matters most is that emergency vehicles can be seen and make people aware of their presence on the road so that people can move out of the way faster. And the greater control and number of options provided by LED lighting is what has made them the ideal lighting option for modern emergency vehicles.

An important feature of LED lights is their size. Because they’re much smaller than the lights that came before, they can be located more easily in different places and on different parts of the vehicle. For example, LED lights have made creating custom grille lights and wing mirrors much easier.

Flashing and Strobe Effects

It’s possible for LED lights to flash, as you’d expect and that’s obviously what’s wanted and what’s necessary when it comes to creating emergency vehicle lighting solutions. They can do so in a convenient and efficient way, and offer a range of effects and flashing patterns that can be used depending on the needs of the vehicles using them.

There’s also a range of strobe effects that can be employed by LED lights attached to emergency vehicles. Research is still being carried out to this day into which types of strobe light patterns, colours and placements are best at alerting drivers to the presence of emergency vehicles in the fastest and most effective way possible.

There are many potential ways in which LED strobe effects might be tweaked and changed going forward. This again comes back to the flexibility and versatility of LED emergency vehicle lights and construction lights for trucks compared to the kinds of lights that were used before.

LED Information Matrix Signs

LED information matrix signs are also very commonly used by emergency vehicles these days. They offer a range of functions and benefits that simply aren’t offered by other lighting options. LED information matrix signs allow emergency vehicles to display particular words and messages to give out specific information when it’s necessary or helpful for them to do so.

LED information matrix signs when used by emergency vehicles are often positioned on the roof of the vehicle. For example, you might see police cars with LED information matrix signs positioned between two blue beacon lights. They can then be programmed to display any message that needs to be displayed, and this will be dictated by the scenario in which they’re being used.

Among their many practical applications is usage in traffic stops. A police car might be following a car that needs to be pulled over, and one of the tools that can be used to make that happen is a message telling a vehicle to pull over displayed on the police car’s LED information matrix sign.

Mounting

There are various different types of mounting for LED lights on emergency vehicles. Mounting positions are generally decided by the needs and design of a vehicle and where it makes most sense to place them. There are, however, certain places where they’re most likely to be positioned for visibility reasons. These include beacons on the roof, grille flashers, wing mirror flashers, visor signs and lightbars on the roof and grille of the vehicle.

Body mounted emergency vehicle lights are very commonly used as well. These are especially common on ambulances and larger emergency vehicles. They can also help by adding additional subtlety, which is important for police cars that are going undercover.

Similarly, LED vehicles often use interior lights when subtlety is important. As well as being more hidden when not in use, interior mounted lights also allow emergency vehicles to be more aerodynamic and streamlined when the vehicles are moving.

That’s the background you need to know about LED strobe lights, how they came to be, how they're made and how they’re used by emergency vehicles. It’s an interesting history and the technology is still being pushed in new directions and being used in new ways, so there’s more to come from the story of LED lights.